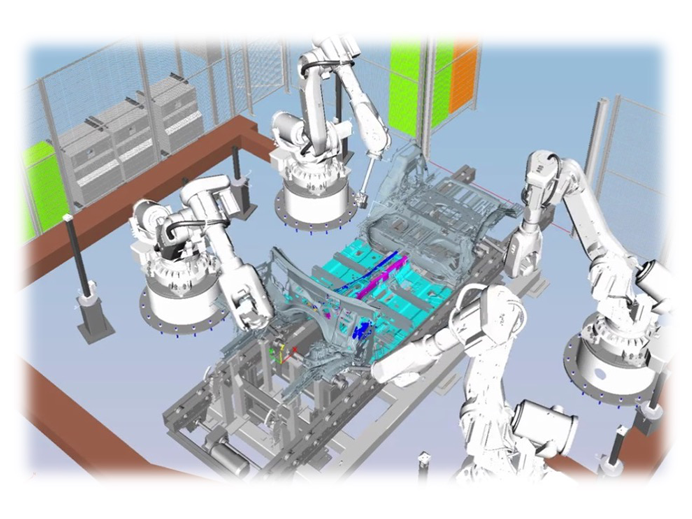

The eddy current spot weld inspection host has a battery standby time of over 12 hours. It comes standard with four lithium batteries for the industrial-grade laptop, along with a battery charging dock, enabling full-day testing without the need for an external power source or shutting down the system to replace batteries.

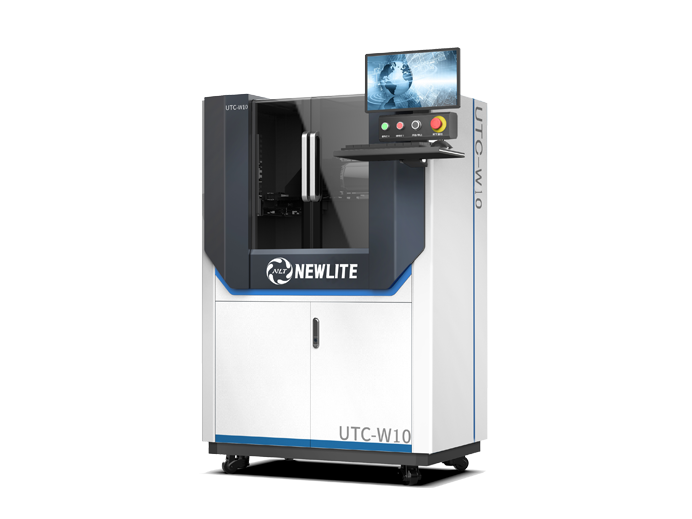

The application and proportion of hot-formed steel and high-strength steel plates in car body welding are increasing. For those who are familiar with using ultrasonic equipment to detect weld spots, the operation is difficult. It is difficult to detect sticky welds and weak welds, and a large amount of coupling agent must be applied., the existence of many problems such as the unknown welding strength of weld joints has never been well solved. The bottleneck of ultrasonic technology in weld spot inspection has become more and more obvious.

With the advent of the application era of eddy current technology in weld spot inspection, the accuracy of qualitative and quantitative methods has raised weld spot inspection to a new level.

Industrial Integrated Equipment

Enhanced Protection

In-Depth Inspection

Quick Operation

Portable

- Eddy current technology directly analyzes the material changes in weld spots after welding and has a very high detection rate for false and adhesion welds.

- Measurement data quantification: directly calculate the nugget diameter; heat-affected zone diameter; and relative weld spot strength.

- Electromagnetic induction technology, There is no need to apply any intermediate medium on the surface of the solder joint during inspection, such as a coupling agent or grease.

- Simple operation, safe to use, high accuracy of test results, and measurement reports can be exported in multiple formats.

Fully communicate with customers, conduct in-depth exploration, and accurately identify pain points and demand points in business processes

Discuss feasibility with clients and confirm customized solutions tailored to their needs.

Assign designated project managers, engineers, trainers, etc. to follow up and ensure the successful implementation of the project.