Newlite Water Immersion C Scan helps civil aviation aircraft engine inspection!

NDT Laboratory of Zhuhai MTU Aero Engines Maintenance Company

NDT Laboratory of Zhuhai MTU Aero Engines Maintenance Company

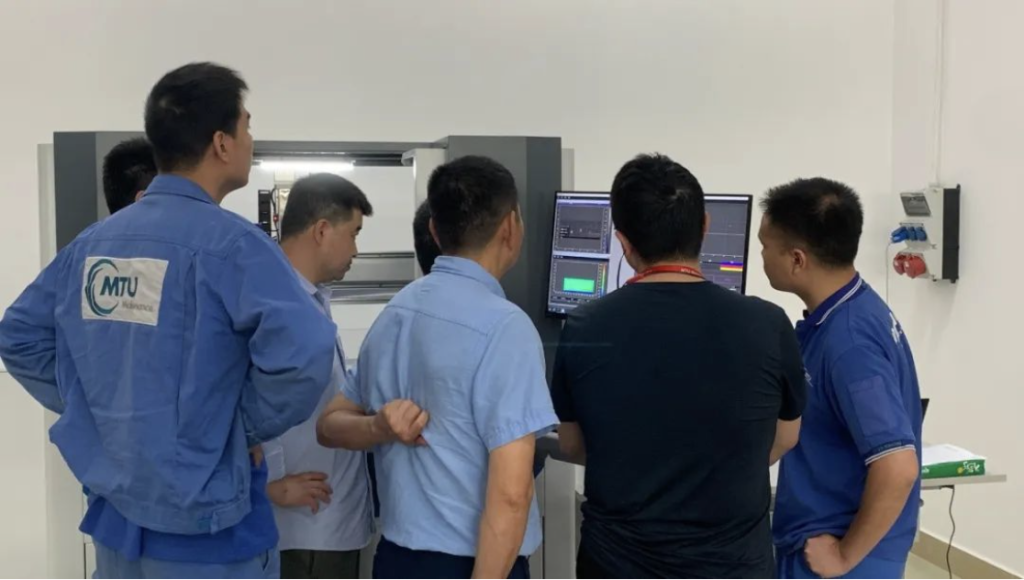

The ultimate goal of all industries is to serve the people, and the reputation we hold determines the quality of our products. Zhuhai MTU is a joint venture company that repairs aircraft engines. The quality of aircraft engines directly impacts the safety of every flight, so it cannot be taken lightly. We are very honored to be able to join this big family that protects safety. From 10th April to 12th April 2024, we went to Zhuhai MTU Aero Engines Maintenance Company for another after-sales training on ultrasonic water immersion. During this training, every participant had a strong interest in our equipment and operated it by themselves. After professional explanation and learning, they inspected different workpieces, analyzed the defects, and derived the reports.

City:

Classification:

Product:

Start date:

End date:

Keywords:

Zhuhai

User Training

Ultrasonic Water Immersion C-Scan System

April 10, 2024

April 12, 2024

Automotive, Ultrasonic Water Immersion C-Scan

This training aims to help your company’s employees:

- Gain an in-depth understanding of the principles, structure, and usage of ultrasonic water immersion C-scan equipment.

- Master daily operations, maintenance, and troubleshooting skills of the equipment.

- Improve detection efficiency and accuracy through practical case analysis.

- Overall introduction and functional demonstration of the equipment

- Explanation of equipment operation methods and techniques

- Guidance on equipment maintenance and upkeep

- Sharing of common fault analysis and solutions

- On-site practical exercises and Q&A

This training is aimed at the relevant staff of Zhuhai Motianyu Company who have purchased the ultrasonic water immersion C-scanning equipment.

This training is conducted by professional and technical staff from Shanghai Newlite Industrial Co., Ltd. They have rich practical experience and profound expertise and can provide you with high-quality training services.

After the training was completed, on April 12th, each student chose different types of workpieces for assessment. They skillfully handled the settings of various parameters in the software, adjusted the distance between the workpiece and the probe, analyzed defects after detection, and exported reports. Each participant mastered these tasks very well, and the entire training task was completed successfully.

Our main customers:JAC, GEELY, DONGFENG PEUGEOT CITROEN, CHERY, VOLKSWAGEN GROUP, FAW GROUP, SGMW, FAW TOYOTA, COSMA, BORGWARD, BMW, BAIC BJEV.